(1) How is your R & D capacity?

Our R & D department has a total of 10 personnel, and 6 of them have professional experience in large communication companies , such as: Senko, Huawei, Molex, Seikoh Giken and H&S. In addition, our company has established R & D cooperation with 5 universities and 4 research institutions in China. Our flexible R & D mechanism and excellent strength can satisfy customers’ requirements.

Please contact us for further information.

(2) What is the difference between your products in the industry?

Our products adhere to the concept of quality and delivery time first and satisfy the needs of customers.

Please contact us for further information.

(1) What is your purchasing system?

Our procurement system adopts the 5R principle to ensure the “right quality” from the “right supplier” with “right quantity” of materials at the “right time” with “right price” to maintain normal production and sales activities. At the same time, we strive to reduce production and marketing costs to achieve our procurement and supply goals: close relationships with suppliers, ensure and maintain supply, reduce procurement costs, and ensure procurement quality.

Please contact us for further information.

(2) Who are your suppliers?

At present, we have been cooperated with 25 businesses for 16 years, including Senko, Suncall, H&S, US conec, Corning, YOFC, Fujikura, Seikoh Giken, etc.

Please contact us for further information.

(3) What are your standards of suppliers?

We attach great importance to the quality, scale and reputation of our suppliers. We firmly believe that a long-term cooperative relationship will definitely bring long-term benefits to both parties.

Please contact us for further information.

(1) How long is your normal product delivery period?

The lead time depends on the order quantity. For samples, the delivery time is within 1-2 working days. For mass products, the delivery time is 5-8 working days after receiving the deposit. For Customized products, the delivery time is 18-25 working days.

Please contact us for further information.

(2) What is your total production capacity?

Our total production capacity is approximate 600,000pcs terminals per month.

Please contact us for further information.

(1) What is your quality control process?

Our company has strict quality control process.

Please contact us for further information.

(2) Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates; Reach; RoHS; Origin, and other export documents where required.

Please contact us for further information.

(3) What is the product warranty?

Normally one year guaranty service. However, we guarantee our materials and craftsmanship. Our promise is to make you satisfied with our products.

Please contact us for further information.

(1) Do you guarantee safe and reliable delivery of products?

Yes, we always use high-quality packaging for shipping. We usually use carton box for standard products. We also use special packaging for special goods. Specialized packaging and non-standard packaging requirements may incur additional costs.

Please contact us for further information.

(2) How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the quickest but also most expensive way. By sea freight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way.

Please contact us for further information.

(1) What are the acceptable payment methods for your company?

We support 100% T/T. More payment methods depend on your order quantity.

Please contact us for further information.

(1) What online communication tools does you have?

Our company's online communication tools include Tel, Emails, Whatsapp and Skype

Please contact us for further information.

(2) What is your complaint hotline and email address?

If you have any dissatisfaction, please send your question to info@intcera.com

We will contact you within 24 hours, thank you very much for your tolerance and trust.

Please contact us for further information.

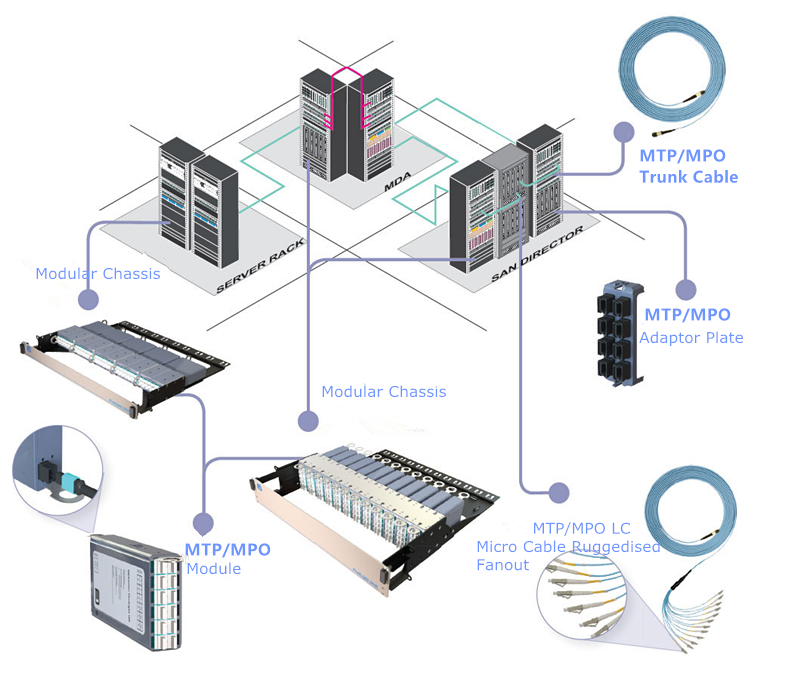

There is no doubt that 40/100/200/400G networks become the trend in today’s cyberspace. Many applications are pursuing the high bandwidth throughput, therefore using high-density patching is inevitable. But is there any good solution for high-density structured cabling? Definitely, MTP/MPO system solves your trouble with a wide range of MTP/MPO assemblies. It is a technique enabling multi-fiber connections to be used for data transmission. The high fiber count creates the endless possibilities of high-density patching. The easy installation of MTP/MPO assemblies also saves lots of operating time. There will introduce some regular MTP/MPO products and their common applications.

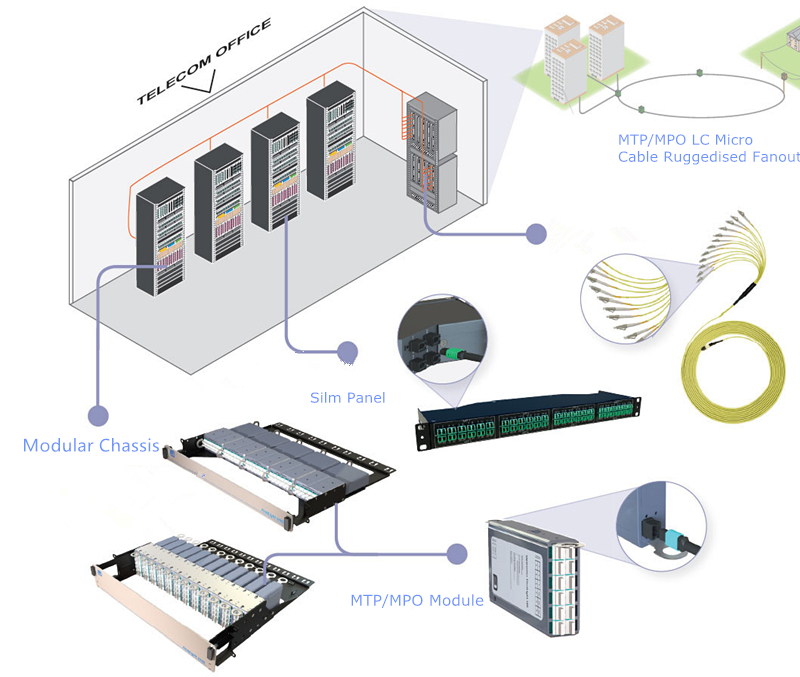

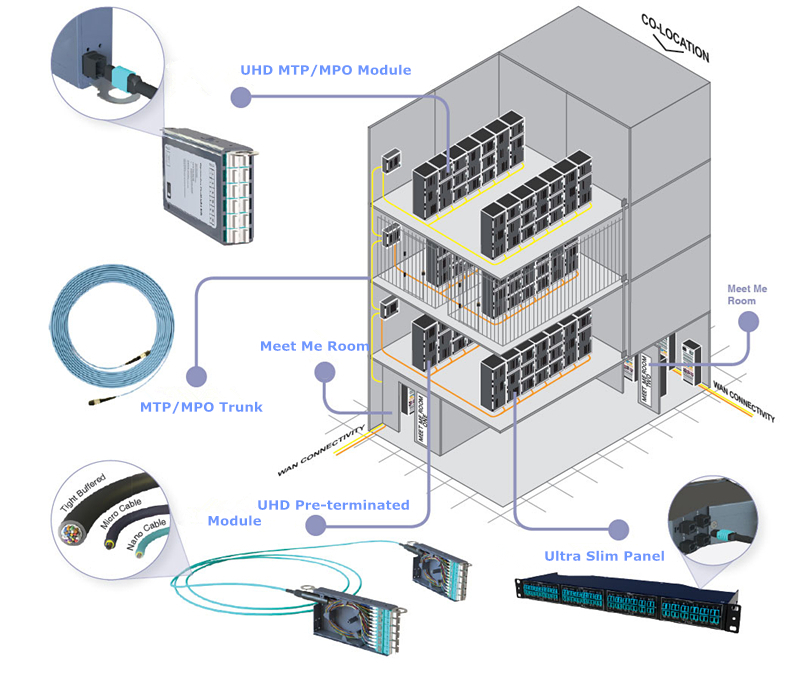

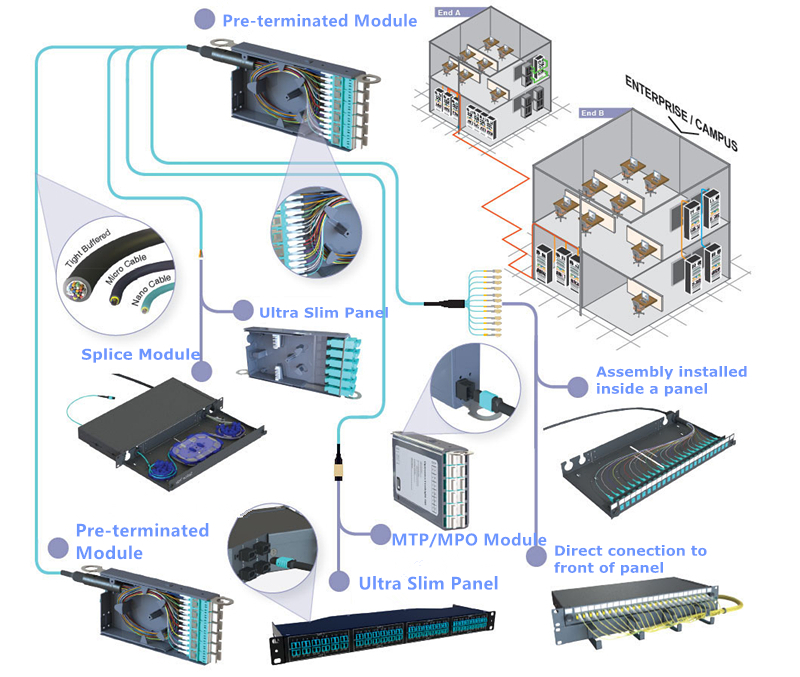

To accommodate the needs for high speed networks, MTP/MPO system has many optics to fit for different applications. There are usually MTP/MPO cables, MTP/MPO cassettes, MTP/MPO optical adapter and MTP/MPO adapter panels.

MTP/MPO cables are terminated with MTP/MPO connectors at one end or both ends. The fiber types are often OM3 or OM4 or OM5 multimode optical fibers. MTP/MPO cables has three basic branches of trunk cables, harness/breakout cables and pigtail cables. MTP/MPO trunkscan be made with 8, 12, 24, 36, 48, 72 or even 144 fibers for single-mode and multimode applications. MTP/MPO harness cables are usually terminated with a MTP/MPO connector at one end and different connectors, such as LC, SC, ST connectors, etc. at the other end. Pigtails only have one end terminated with a MTP/MPO connector, and the other end is used for fiber optic splicing with no termination.

As for theMTP/MPO cassettes, they are equipped with standard MTP/MPO connectors to be deployed in an ODF (optical distribution frame) for high-density MDA (main distribution area) and EDA (equipment distribution area) in data centers.

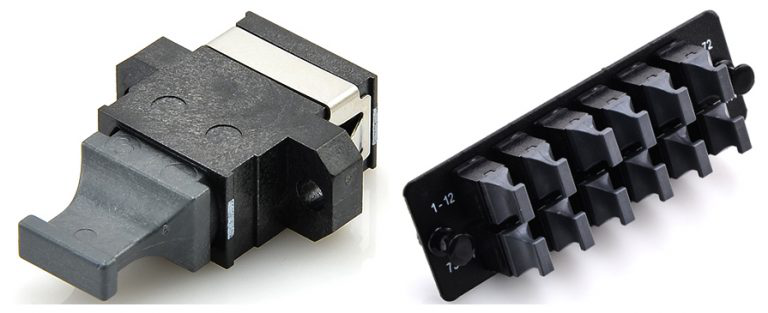

Other components like the black-colored MTP/MPO optical adapter and adapter panels build the connection between MTP/MPO cable to cable or cable to equipment.

Terminates ribbon fiber or loose individual fibers

Ruggedized round cable, oval cable and bare ribbon options available

Compatible with US Conec MT ferrules in fiber counts 4 – 24

Color coded housings available to differentiate fiber type, polish type and/or connector grad

Housing is removable for quick change of pin clamps and easy ferrule cleaning /re-polishing

No-epoxy housing design

Family of bulkhead adapters available

MPO style connectors that are compliant to industry standards are inter-mateable with the MTP connector. This means that changing from 1 style connector to the MTP connector and getting higher levels of performance is possible.

MTP connector is fully compliant with – FOCIS (aka TIA-604-5) – IEC-61754-7 – CENELEC EN50377-15-1 The MTP brand connector components are fully compliant with IEC Standard 61754-7 and TIA 604-5 – Type MPO.

As the new favorite of data center, the MPO/MTP solutions feature the following advantages:

Rapid Deployment

Since the MPO/MTP products are factory terminated, they can be installed easily and simply. They use a simple push-pull latching mechanism for easy and intuitive insertion and removal. Thus, the installing process only includes pull and plug, eliminating all unpredictable field termination troubles. It is estimated that the MPO/MTP solutions’ installation time can be reduced by up to 75% compared to traditional fiber cabling systems.

High Density

Being the same size as a SC connector, the MPO/MTP connector can accommodate 12/24 fibers, providing 12/24 times the density. Therefore, MPO/MTP connectors allow high-density connections between network equipment in telecommunication rooms, and offer savings in circuit card and rack space.

Cost Saving

As mentioned above, the installation process of MPO/MTP products is simple and easy. Therefore, the installation time involving a costly highly qualified workforce can be reduced to a minimum.

Scalability

As we all know, most MPO/MTP products are modular solutions. This is the good choice to ease future expansion and for quick and easy system reconfiguration.

Conclusion

40/100/200/400G Ethernet is the developing trend in data center cabling system. Therefore, MPO/MTP cabling system becomes the ideal solution for the growing demands on high-capacity cabling data center. INTCERA provides a series of MPO/MTP solutions which are plug and play, simple installation, compact design and high precision. For more information, please contact us over sales@intcera.com.

With the advent and popularity of cloud computing and big data, the demands for high-speed transmission and data capacity are becoming much greater than ever before. And 40/100/200/400G Ethernet is now a trend and hotspot for data center cabling system. Since MPO/MTP connectors are the up-and-coming standard optical interface for 40/100/200/400G Ethernet network, it is predicted that MPO/MTP solutions will eventually flood the data center. After all, the high fiber count in one connector creates endless possibilities.

There are features on the MTP connector that have been specially designed to give improved performance and better usability over generic MPO connectors. These design features are unique to the MTP and are patent protected. The key features are described below:

1. The MTP connector housing is removable.

Re-work and re-polish of the MT ferrule ensures overlife performance.

The gender can be changed after assembly or even in the field giving flexibility at point of use.

The ferrule is scanned interferometrically after assembly.

2. The MTP connector offers ferrule float to improve mechanical performance.

This allows two mated ferruled to maintain physical contact while under an applied load. (US Patent 6,085,003)

3. The MTP connector uses tightly held tolerance stainless steel elliptical guide pin tips. The elliptical shaped guide pin tips improve guidance and reduces guide hole wear. (US Patent 6,886,988)

4. The MTP connector has a metal pin clamp with features for centering the push spring. This feature:

Eliminates lost pins

Centers the spring force

Eliminates fiber damage from the spring mechanism

5. The MTP connector spring design maximizes ribbon clearance for twelve fibers and multifiber ribbon applications to prevent fiber damage.

6. The MTP connector is offered with four standard variations strain relief boot giving more flexibility over the cable used

A round loose fiber cable construction

Oval Jacketed Cable

Bare Ribbon Fiber

Short boot which reduces the footprint by 45%. Ideal for use in space limited applications.

Array trunk cables / Array fiber to single fiber fanouts and cassettes

High fiber density card edge access / Optical switching interframe connections

IEC Standard 61754-7 / TIA/EIA 604-5 Type MPO Structured cabling per TIA-568-C Parallel Optics / Optical Internetworking Forum

(OIF) Compliant Infiniband Compliant / 10G Fiber Channel Compliant / 40G and 100G IEEE 802.3 SNAP 12 / POP 4 / QSFP

MPO is the industry acronym for “multi-fiber push on.” MPO connectors have more than 1 fiber in a single ferrule and snap into place by a mechanical mechanism.

The MTP Connector is one brand of MPO connector.

Due to the difficulties in mating two connectors with multiple fibers, as opposed to using single fiber connectors such as an LC connector, different brands of MPO give different performance.

The term MPO stands for Multi-fiber Push On and is a specific interface type. The MPO interface was developed to enable multi-fiber connectivity for higher density, higher bandwidth based applications requiring parallel or channel based optics. 12 and 24 fiber versions are currently used to direct connect into 40G and 100G transceivers and also used in high density fiber distribution areas. Higher fiber versions are also available (48, 72 fiber) but their use and deployment is currently limited.

The MTP® connector is specifically a brand of MPO interface connector that is owned by the leading US based optical R&D company US Conec. Like MPO it is based on the MT (mechanical transfer) ferrule technology which was developed by Nippon Telephone and Telegraph (NTT) during the 1980s.

A floating ferrule that aids in accurate alignment and improves performance of mated ferrules under stressed load conditions.

Elliptical guide pins that allows for better alignment by improving mating guidance and reducing hole wear.

Removable housing allowing for smoother transition of gender types in the field and easier access to performance testing and re-work of the MT ferrule.

The MTP® connector has a metal pin clamp that centers and guides the push spring. This feature eliminates lost guide pins, centers the spring force and eliminates damage to fiber cables from the spring.

The MTP® connector spring design maximizes ribbon clearance for twelve fiber and multi-fiber ribbon applications to prevent fiber damage.

The MTP® connector is offered with four standard variations of strain relief boots to meet a wide array of applications.

The MTP® connector is currently available in 4, 8, 12, 24, and 72 fibers densities for multimode fiber (50µm and 62.5µm core) and 4, 8, 12, and 24 fibers densities for single-mode fiber, as well as the MTP® Elite® (low-loss) single-mode connector in both 8 and 12 fibers densities. It is also important to note that the MTP® connector complies with the MPO standard as outlined in IEC standard 61754-7 and TI-604-5 and is therefore a fully compliant MPO connector and can interconnect directly with other MPO based infrastructures.

MPO is the industry acronym for “multi-fiber push on.” MPO connectors have more than 1 fiber in a single ferrule and snap into place by a mechanical mechanism.

The MTP Connector is one brand of MPO connector.

Due to the difficulties in mating two connectors with multiple fibers, as opposed to using single fiber connectors such as an LC connector, different brands of MPO give different performance.

Typically, MPO connectors have had 12 fibers or multiples of 12 fibers (24, 48, 72). However, recently 8 fiber MPO connectors are being introduced to accommodate the uptake of BASE-8.

There are many designs of MPO on the market from the various manufacturers. The high end performance marketplace is dominated by the MTP connector. This connector offers reliable performance and the MT ferrule used in the connector is also used by many brands of equipment (CISCO, Brocade etc.) within their transceivers. By using the same ferrule in the transceiver and the connector cable ensures the highest performance.

We believe the market leading MPO connector in terms of performance and durability is the MTP® connector produced by US Conec – which is why our range is standardised on this product and is also probably why the connector is used by many other brands including Corning, Systimax by Commscope, TYCO Amp Net Connect / ADC Krone, Panduit, Siemon and many others.

Are MT Ferrules Cleaned in the Same Way as Standard Connectors?

The best method available for cleaning MT ferrules to remove dust and oils which reduce optical performance is the use of an advanced dry cloth cleaning system like the IBC branded cleaning tool or an NTT-AT OPTIPOP.

The cleaning method is very simple as it involves a single pass. When using the recommended cleaning system contaminants are completely removed as opposed to using low grade cloths or swabs which just move the contaminants away from the fibers but leave them on the ferrule face.

1. The click cleaners and OPTIPOP family of cleaners are designed for use with both male and female connections and have options for single fiber ceramic ferrule connectors as well

2. The OPTIPOP cassette and card cleaners allow the owner to refill the cleaning clothes which can reduce cost per cleaning below traditional cleaning methods.

There are two aspects to the connector; the housing and the ferrule. There are multiple options of both which are used for different fiber core counts and different construction cables.

MT stands for mechanical transfer and an MT ferrule is a multi-fiber (usually 12 fibers) ferrule. The performance of the connector is determined by the fiber alignment and how this alignment is maintained after connection. Ultimately, the alignment is determined by the eccentricity and pitch of the fiber and how accurately the guide pins keep the fibers together during mating. The performance of any MPO connector can be improved if the tolerances of the pins and the moulding processes are reduced during manufacture.

INTCERA.COM, as a fiber network solution supplier, is now going to be ahead of the game with various MPO/MTP solutions that are designed for the reliable and quick operations in the data center. We offer a wide range of MPO/MTP solutions including trunk cables, harness cables, cassettes, fiber enclosure and so on.

As the era of 40/100/200/400G network is coming, traditional LC cabling is no longer able to satisfy the demands for high data rate and high density in data center. The MPO/MTP cabling features replacing 12 or 24 LC connectors with one MPO/MTP connector, which is a high density, high performance solution for fast installation of enterprise data center and other high count cabling implementation.

UHD system modules can be installed in enterprise or campus networks using “plug and play” MTP/MPO or “just play” pre-terminated modules. Installation is fast and easy, which requires no professional fiber optics knowledge. Traditional splicing installation techniques can also be applied. There is a wide selection of cable types including tight buffer, loose tube, micro cable, etc. for employment

MTP/MPO plug and play modules have been widely used in data centers, such as backbone products supporting hundreds of optical ports. Therefore, single cabinets must hold quantities of optical interconnections and patch cords. Since SAN needs high-density and modular cabling for easy reconfiguration, MTP/MPO plug and play modules are perfect to meet the requirements of these infrastructures.

In a word, MTP/MPO system is a perfect solution suited for high-density applications. The MTP/MPO products are designed to be space-saving and easy to manage. Initial investment for MTP/MPO assemblies might be expensive, but it is a wise and cost-effective decision to deploy the system for your application in the long run.